3M DI-NOC installers NYC bring unparalleled expertise to commercial space resurfacing by combining precision installation techniques with advanced PVC film technology. These certified professionals apply self-adhesive architectural vinyl film that mimics natural materials such as wood grain, stone, and metal, creating high-end finishes without extensive downtime. Businesses in New York City benefit from minimal disruption as these films adhere seamlessly to flat or curved surfaces, eliminating demolition and waste. Facility managers appreciate the air-release Comply Adhesive™ technology, which ensures bubble-free application even in high-traffic environments. Ultimately, engaging 3M DI-NOC installers NYC means achieving a sophisticated aesthetic while preserving operational continuity in any commercial setting.

What makes 3M DI-NOC architectural finishes stand out?

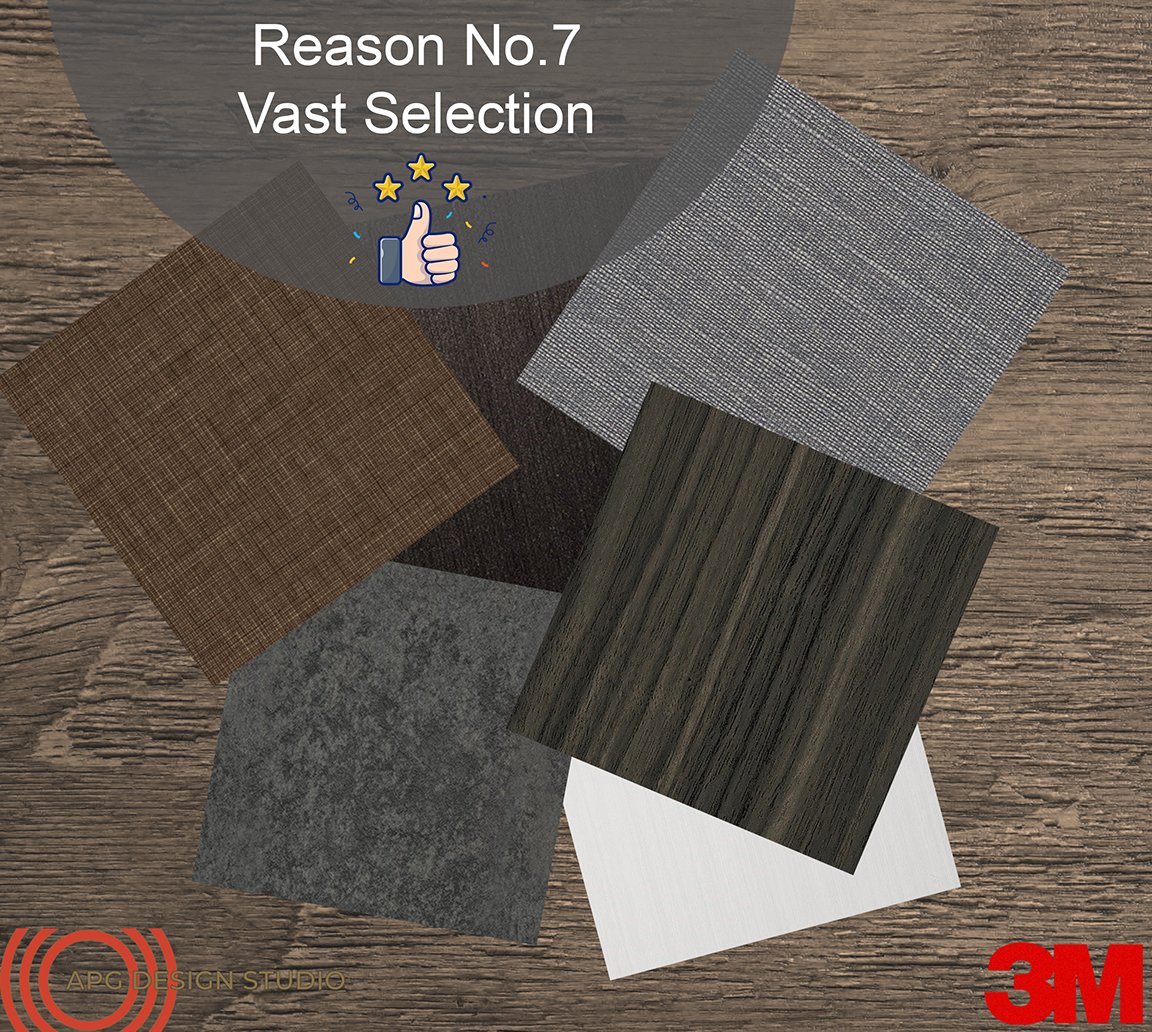

3M DI-NOC architectural finishes redefine interior surface renovation by delivering tactile depth and dimensional realism unlike traditional decorative films. These multi-layered finishes incorporate a high-performance wear layer, decorative film, and premium adhesive backing to withstand heavy usage and frequent cleaning. Over 900 patterns offer designers virtually limitless creative freedom, from refined wood grains and industrial metals to natural stone and textile textures. Each design is engineered to resist UV fading, moisture, and abrasion, providing a durable alternative to paint, wallpaper, or natural materials. This versatility empowers architects and interior designers to execute bold design concepts with budget-friendly materials that rival the authenticity of conventional renovations.

Key features of architectural vinyl film in commercial space resurfacing

Architectural vinyl film serves as a cornerstone of modern commercial space resurfacing by offering rapid installation coupled with sustainable credentials. These films require no solvent-based adhesives, reducing volatile organic compounds (VOCs) and supporting healthier indoor air quality. With heat-activated conformability, installers can wrap columns, elevator cabs, ceilings, and furniture with minimal cutting and trimming. The inherent flexibility of the film accommodates complex geometries and tight radii, ensuring a flawless finish on challenging surfaces. Additionally, the ability to earn LEED credits makes architectural vinyl film an attractive solution for green building initiatives, aligning aesthetic goals with environmental stewardship.

Comparing 3M DI-NOC to traditional renovation materials

The table below illustrates how 3M DI-NOC compares to conventional renovation materials in key performance areas:

| Feature | Traditional Materials (Wood, Stone, Metal) | 3M DI-NOC Architectural Finishes |

|---|---|---|

| Weight | Heavy, requires structural support | Lightweight film, no additional framing needed |

| Installation Time | Weeks to months (demolition, fabrication, finishing) | Hours to days, depending on scale |

| Cost | High labor and material expenses | Lower overall cost with predictable budgets |

| Environmental Impact | Waste generation, high carbon footprint | Minimal waste, recyclable components |

| Maintenance | Prone to scratches, moisture damage, requires refinishing | Abrasion-resistant, moisture-proof, easy to clean |

| Design Flexibility | Limited by material availability and fabrication complexity | Over 900 patterns, easily changed or updated later |

Understanding the installation process of interior surface renovation films

The interior surface renovation workflow for 3M DI-NOC involves meticulous surface preparation followed by precision film application. Initially, installers assess substrates for smoothness, filling seams or imperfections with compatible fillers. After thorough cleaning with isopropyl alcohol, the air-release adhesive enables swift bubble-free placement. Using a heat gun, the film conforms to curves and edges without overstretching, preserving pattern integrity. Final squeegeeing removes any residual bubbles, and trimming ensures neat edges. This systematic approach results in a uniform finish that can be occupied immediately, minimizing business interruptions and accelerating project timelines.

Product types: 3M DI-NOC E-Series, Finishes, and Whiteboard

3M DI-NOC offers three primary product categories tailored to diverse applications within commercial interiors:

| Product Type | Application | Key Feature |

|---|---|---|

| E-Series | Exterior façades, storefronts, signage | Weather-resistant, UV-stable, ideal for exterior use |

| Finishes | Walls, ceilings, furniture, doors | Realistic textures, over 900 patterns |

| Whiteboard Finishes | Collaborative spaces, training rooms, classrooms | Writable surface, easily erase marker residue |

Each category delivers specialized performance—E-Series for building envelopes, Finishes for aesthetic upgrades, and Whiteboard Finishes for interactive environments.

Real-world applications in hospitality and retail environments

Hotels and retail tenants often leverage 3M DI-NOC to refresh lobbies, display areas, and customer-facing fixtures with minimal disruption. The ability to match existing brand palettes with custom film prints ensures visual consistency across multiple locations. Concierge desks can be wrapped in rich walnut wood grain finishes, while fitting room doors adopt elegant metallic sheens for a modern boutique appeal. The rapid installation process allows high-end hotels to renovate public areas overnight, avoiding guest inconvenience. In retail, seasonal campaigns and window displays gain renewed impact as surfaces transform easily without the need for extensive construction.

Sustainable and LEED-compliant benefits of 3M DI-NOC

In an era of increasing environmental scrutiny, 3M DI-NOC stands out for its eco-responsible manufacturing and reduced waste profile. The films utilize water-based inks and solvent-free adhesives, significantly lowering VOC emissions during application. Because existing substrates remain intact, waste from demolition and disposal is virtually eliminated. Project teams can contribute toward LEED credits under Materials & Resources categories for reuse of existing materials and low-emitting adhesives. Moreover, the optional E-Series enhances building envelope performance by reflecting solar heat, reducing HVAC loads and improving energy efficiency.

Achieving brand consistency with design flexibility

Interior design agencies seeking cohesive brand experiences often integrate textured surface finishes with coordinated graphics and signage. To achieve this, many firms collaborate with Creative Packaging & Print Solutions to develop custom wall graphics and wayfinding that complement the subtle wood, stone, and textile patterns of DI-NOC films. This intersection of architectural vinyl film and bespoke printed elements ensures that every touchpoint—from reception signage to directional markers—harmonizes with the overall interior palette. The result is a unified spatial narrative that reinforces corporate identity and customer recognition across multiple touchpoints.

Integrating surface finishes with protective window films for safety and style

Commercial projects frequently demand both aesthetic upgrades and enhanced security features. By specifying 3M Safety Window Films alongside DI-NOC, property managers can simultaneously address interior surface renovation and glass protection. Safety films adhere to glazing and reinforce glass against impact, reducing the risk of shattering. When used in tandem, these films create a holistic upgrade, with interior finishes reflecting cohesive textures while windows deliver both style and safety compliance. This integrated approach caters to high-traffic retail centers, educational facilities, and healthcare environments where occupant safety is paramount.

Coordinating wall treatments and glazing with complementary films

Contemporary offices and coworking spaces benefit from transparent partitions that maintain a sense of openness while delineating meeting areas. Applying DI-NOC to opaque walls and pairing glass panels with decorative Window Films enables designers to blend privacy film patterns with adjacent surface textures. For instance, a brushed metal film on doors can align seamlessly with frosted glass stripes, fostering consistency in material language. This strategy empowers facility planners to control sightlines and acoustics while upholding a polished, branded aesthetic throughout workspaces

Calculating ROI: cost and time savings of 3M DI-NOC installations

Investing in 3M DI-NOC can yield rapid returns through lower material costs, reduced labor hours, and minimal business disruption. Traditional renovations often entail multiple trades—demolition crews, carpenters, painters—driving up project duration and budgets. In contrast, DI-NOC requires a single specialized installation team and can often be completed during off-hours. Facility managers report up to 50% savings on total project cost and a dramatic reduction in downtime, enabling spaces to remain operational or reopen swiftly. When aggregated across multiple sites, these efficiencies contribute to significant bottom-line improvements.

How long does a typical installation take?

Project timelines vary based on square footage, surface complexity, and environmental factors, but most standard office suites can be fully wrapped within two to four business days. Smaller retail kiosks or elevator interiors might be completed overnight, ensuring zero loss of trade. The rapid pace is facilitated by the air-release Comply Adhesive™, which allows installers to reposition film panels quickly without trapping air pockets. Binding schedules around off-peak hours further enhances efficiency, making DI-NOC an ideal choice for businesses seeking swift turnarounds without sacrificing finish quality.

Factors affecting installation time and project planning

Several variables influence overall timeline accuracy, including substrate smoothness, film selection, and site access constraints. Pre-project surveys identify critical dimensions, allowing for prefabrication of film panels and minimizing on-site adjustments. Coordinating with building management to secure after-hours access reduces workflow interruptions. For exceptionally large projects, APG Design Studio recommends phased installation to ensure core business operations remain unaffected. This level of strategic planning makes 3M DI-NOC installations both predictable and transparent from a scheduling perspective

Ensuring longevity: maintenance and durability of DI-NOC finishes

Once installed, 3M DI-NOC films deliver years of service with minimal upkeep. Routine maintenance involves gentle cleaning with mild detergent and water, preserving both finish vibrancy and adhesive integrity. The protective wear layer guards against scratching and staining, making it suitable for high-traffic corridors, elevator interiors, and reception desks. In the event of damage or design refresh, individual panels can be replaced without rewrapping entire surfaces, further extending the lifecycle and reducing lifecycle costs. Customers often report the films look ‘like new’ even after heavy commercial use.

Selecting certified 3M DI-NOC installers NYC for quality assurance

Choosing accredited professionals guarantees adherence to 3M’s rigorous installation standards and warranty requirements. Certified 3M DI-NOC installers undergo extensive training that covers substrate preparation, film handling, and finishing techniques. APG Design Studio meticulously vets local contractors, confirming installation crews carry the latest tools and follow best practices. This quality assurance process ensures films perform as expected and maintain manufacturer warranties. Businesses engaging certified teams benefit from documented project plans, precise timelines, and final inspections that adhere to 3M’s stringent specifications.

Case study: Office lobby transformation in Manhattan

A leading financial firm in Midtown Manhattan revitalized its lobby through commercial space resurfacing using DI-NOC wood grain finishes. The project encompassed elevator cabs, reception walls, and column wraps totaling over 2,500 square feet. By scheduling installations overnight, the firm avoided any interruption to morning client traffic. Post-installation surveys reported 95% employee satisfaction with the new environment, praising the warmth and coherence of the design. The rapid execution and minimal debris demonstrated how 3M DI-NOC installers NYC can deliver premium results under tight urban constraints.

Best practices for preparing surfaces for vinyl film application

Proper surface preparation is foundational to successful film adhesion and longevity. Start by filling and sanding drywall joints and patching any cracks or blemishes. Remove wall fixtures and clean surfaces thoroughly with isopropyl alcohol to eliminate dust, oils, and residual compounds. Temperature control within the workspace—maintained between 60°F and 80°F—ensures optimal adhesive performance. Training installers to follow these protocols prevents alignment issues and edge lifting, guaranteeing a seamless finish that resists peeling even under continuous use.

Innovations and future trends in commercial interior renovation

Industry advancements point toward increasingly sophisticated film technologies, including antimicrobial coatings, enhanced fire resistance, and digitally printed patterns for hyper-custom applications. Integration with smart building systems may enable films that adjust opacity or display dynamic graphics on command. As sustainable design continues to drive decision-making, manufacturers are exploring fully recyclable film backings and bio-based adhesives. For architects and facility managers, staying abreast of these trends ensures that renovations using architectural vinyl film remain at the cutting edge of commercial interior design.

Frequently Asked Questions

What surfaces can 3M DI-NOC be applied to?

3M DI-NOC is designed for a wide range of non-porous substrates, including drywall, metal panels, glass, and certain plastics. Its flexibility allows it to conform to flat, curved, and ribbed surfaces, making it suitable for walls, ceilings, columns, doors, and furniture facades. The key requirement is a smooth, clean surface that has been properly prepared to ensure optimal adhesion.

How long does 3M DI-NOC installation typically last?

Under normal commercial conditions, 3M DI-NOC finishes maintain their appearance and performance for up to ten years. The protective wear layer resists abrasion, moisture, and stains, while the high-performance adhesive layer prevents edge lifting. Regular cleaning with mild detergent and water helps preserve the finish and extend service life.

Is 3M DI-NOC durable in high-traffic commercial spaces?

Absolutely. 3M DI-NOC films are engineered to withstand the rigors of busy environments such as lobbies, corridors, and retail areas. Their multi-layer construction delivers superior impact resistance and scratch protection, ensuring that high-touch surfaces remain pristine even under constant use.

Can 3M DI-NOC be removed or replaced later?

Yes, DI-NOC films can be removed cleanly, leaving the underlying surface intact when done correctly by certified installers. Additionally, individual panels can be replaced to refresh patterns or fix localized damage without rewrapping entire walls, enhancing flexibility and lifecycle cost management.

Does 3M DI-NOC contribute to LEED or sustainability goals?

3M DI-NOC supports several LEED MasterSpec® credits, including recycled content, low-emitting materials, and regional material sourcing. By avoiding demolition and utilizing water-based inks, projects reduce landfill waste and VOC emissions, aligning with green building initiatives and corporate sustainability targets.

Conclusion

By enlisting 3M DI-NOC installers NYC, commercial property owners unlock a transformative approach to interior surface renovation that balances design excellence, sustainability, and operational efficiency. This advanced architectural vinyl film enables rapid updates, long-lasting performance, and rich customization through over 900 patterns suitable for any sector—from office towers to hospitality venues. To embark on a seamless upgrade that fosters brand cohesion and cost savings, APG Design Studio stands ready to leverage certified expertise and industry-leading materials. Businesses seeking turnkey interior refinishing solutions need only contact us to schedule an on-site assessment and discover how 3M DI-NOC can redefine their commercial spaces.